Hydraulic double mold tire curing press

It is applied to the hydraulic curing press for curing the outer tube of hollow tire

- The excellent dynamic and static characteristics of the proportional valve improve the performance of the product and work reliably

- Economical and simple control mode

- Stable operation, small impact and high reliability

Hydraulic double mold tire curing press

- Product introduction

- Related products

- Data download

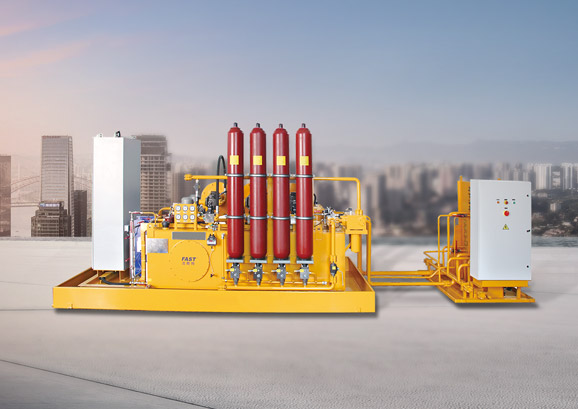

The hydraulic system of hydraulic dual-mode tire curing press is the most important supporting equipment for curing hollow tire outer tube. It is mainly suitable for bias tire and radial tire curing press. Through hydraulic and electrical control system, a series of processes such as tire loading, tire setting, vulcanization and tire unloading can be realized automatically.

Application of proportional technology in hydraulic vulcanizing press:

The speed of opening and closing die cylinder is different in each stage during the round trip. According to this working condition, the proportional technology is applied to the hydraulic system in the design. The excellent dynamic and static characteristics of the proportional valve improve the performance of the product and work reliably.

In the design of the hydraulic system of the hydraulic double mold vulcanizing press, the requirements of various working conditions are fully considered, and the performance requirements of the main engine are met by the most economical and concise control mode, and the features of stable operation, small impact and high reliability are also provided. In order to save space, some relief valves and one-way valves are used to make the hydraulic system compact in structure, simplified in pipeline and convenient in installation.