15/5000 Solid waste environmental protection industry leading hydraulic solutions

Products are widely used in municipal sanitation, living garbage processing, special vehicles, rubber, metallurgy, military industry, Marine engineering, agricultural machinery, textile, electricity, chemical industry, engineering machinery, forging machinery, casting machinery, machine tools and other industries, with major enterprises, colleges and universities has established good relations of cooperation, with excellent quality and thoughtful service has won widespread praise.

In 1980, it became one of the core suppliers of Baosteel Joint Research and Development Center. In 1992, we started to cooperate with Mitsubishi Heavy Industries of Japan in the production of oil cylinders. From the production of spare parts to the assembly of oil cylinders, we inherited Japanese technologies and processes. After entering the 21st century, it has absorbed the technology and process from Germany and The United States. It has unique technology and skills from product design to production process and design and selection of key parts, which ensures the quality, reliability and innovative development of products.

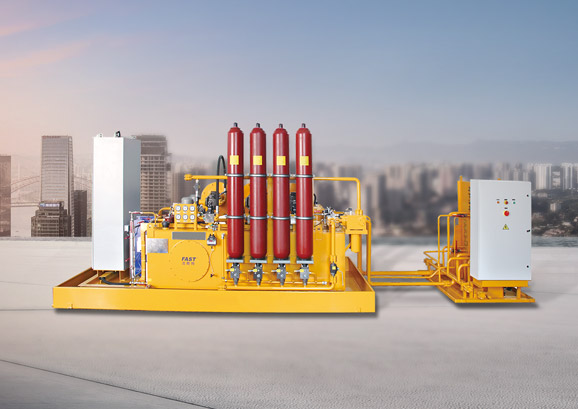

Waste incinerator hydraulic system

Mainly for the mechanical grate type incinerator matching

Up to now, our company has supplied various types of furnaces of various tonnage to many customers in the aspect of waste incineration power grate control hydraulic system. According to the daily processing, there are 250 tons, 300 tons, 350 tons, 400 tons, 500 tons, 600 tons, 750 tons, etc. The furnace type covers Hitachi, Mitsubishi, Martin, Sigus, Denmark Weilun and so on. Because the hydraulic system is the movement center of the incinerator, its stability and durability are the focus of attention, the use of high-quality imported hydraulic components has become the consensus of the industry.

Although each manufacturer's grate control principle is different, but the main structure of the main engine is divided into: feeding grate (also known as pusher), burning grate, slag machine; In addition, there are hopper baffle or broken arch device and other auxiliary parts.

Among them, the structure and control of the combustion grate are the most different, there are push forward, push back and so on. No matter which kind of structure is in order to make garbage in turn through the grate of dry area, combustion area, burn out area, and in this process to make garbage combustion more sufficient, improve furnace temperature, furnace temperature to improve not only conducive to the work of the generator set, but also conducive to the elimination of harmful substances such as two sang Ying.