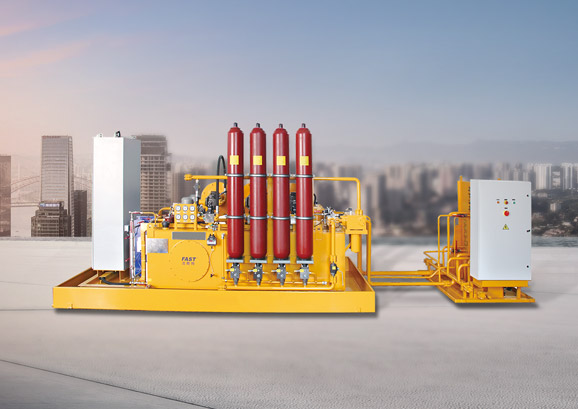

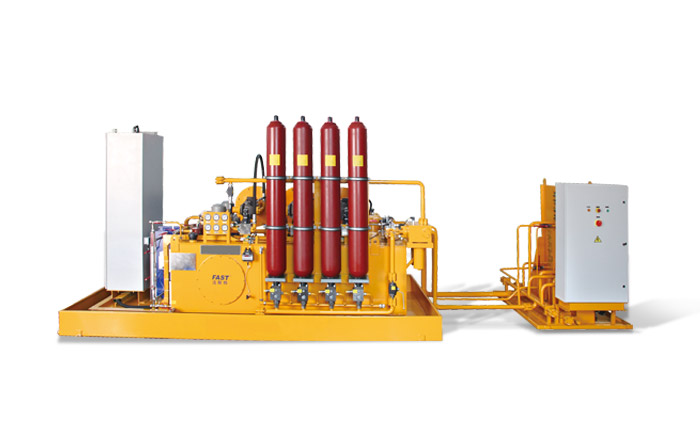

Hydraulic system of grate type domestic waste incinerator

The hydraulic system of incinerator is mainly used for mechanical grate incinerator

- Triple filtration ensures the cleanliness of internal hydraulic oil

- Timely provide alarm signal, oil temperature is normal under high temperature

- Automatic control of cooling and heating system

- Valve block processing technology is mature, burr and inner hole flow channel are handled properly

- The surface nickel plating has excellent anti-oxidation and anti-corrosion effects

- Flange and cone sealing joints conforming to DIN standard and SAE standard are used for pipeline and joint

- Available in stainless steel 304 or even 316

Hydraulic system of grate type domestic waste incinerator

- Product introduction

- Related products

- Data download

The hydraulic system of incinerator produced by our company is mainly matched with mechanical grate incinerator. The feeding, turning and sliding of grate, feeding cover door and slag extractor of mechanical grate incinerator are all completed by hydraulic system.

The components of the incinerator hydraulic system manufactured by our company are mainly Rexroth, ATOS, Vickers, HYDAC and other famous foreign brand products, and can also be designed according to the brand designated by customers.

The main power system adopts the mode of dual-use and one standby and regular rotation, which not only can prolong the service life of the hydraulic pump, but also can maintain and replace it without stopping the machine. Pump and motor, a variety of shock absorption measures are appropriate, stable operation.

The filter system includes pressure oil filter, return oil filter and circulating filter, triple filtration, which ensures the cleanliness of internal hydraulic oil. All filters are double barrel type, which can be replaced without stopping, and alarm for filter block can be provided in time.

The cooler adopts the plate filter with high heat exchange efficiency and is not easy to scale. After the most stringent thermal power check, the oil temperature of the system is normal under high temperature. A temperature sensor is installed in the oil tank to monitor the oil temperature in the oil tank and automatically control the opening and closing of the cooling and heating systems.

All the valve groups are provided with easy maintenance measures, which can maintain or replace any valve group without affecting the operation of other valve groups. The valve block has mature processing technology, proper burr and inner hole flow channel treatment, high smoothness of outer surface after processing, and excellent anti-oxidation and anti-corrosion effect of nickel plating on the surface.

All pipes and joints are made of flange and cone sealing joints in accordance with DIN standard and SAE standard, with reliable sealing and strong interchangeability. Stainless steel 304 or even 316 is available.

According to the daily garbage disposal capacity of the main engine, the hydraulic system is divided into 300t, 350t, 400t, 500t, 750t and other models and specifications.

The hydraulic system of all models and specifications are equipped with electrical control cabinet, which is assembled with the main station and valve station respectively. The structure is compact, and the cable wiring is convenient, neat and beautiful.